Water damage is often an unseen threat under floorboards, carpets, and ceilings, causing environmental and structural destruction such as mold and dry rot. Water leak detection sensors monitor areas for the presence of water and send out alerts before substantial damage is done to electronics or surrounding materials. There are many types of water detection sensors ranging from targeted spot detectors to large zones or perimeter monitoring via cable-type systems. With varying alert functions and possible relay activation, these sensors ensure users are aware of any potential issues and take steps to rectify them.

Spot leak detectors sense water at a single point and are often used in areas like drip pans, floor drains, or where water tends to converge in confined areas. Two probes extend towards the floor, usually with an adjustable supporting bracket to suit different water detection levels. Though economical for specific applications, spot detectors are less suitable for monitoring wide open areas given their small, precise range.

Under carpet leak detectors function similarly to spot detectors, but are extremely slim and compact with no adjustable height in order to fit seamlessly under floor coverings. Alerts are sent when conductive liquid connects the circuit between two probes. Careful placement is necessary as these sensors cover a limited area.

Hydroscopic tape-based (HTB) sensors frequently fasten water sensitive tape to prone structures like water containers and pipes. When exposed to water or moisture, an alarm is triggered. Providing highly sensitive and considerable coverage, these detectors require optimal environments as elements like condensation can trigger false alarms.

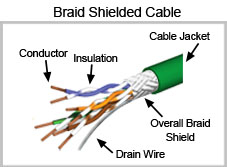

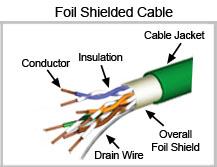

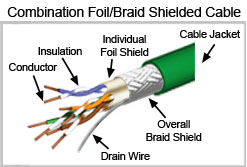

Unlike previously discussed sensors, leak detection cables (rope-style sensors) are designed to cover expansive and open areas. These cables can also be affixed directly to water supply and return lines, making them ideal for covering large spaces with multiple leak points. Conceptually, all leak detection cables are based on two sensing wires running concentrically around the cable. Conductive fluid acts as a switch between both wires by connecting the circuit between them.

Depending on material and quality, these detection cables could have varying levels of bending flexibility, reactive reliability, and susceptibility to false alarms, as dust and dirt can build up over time and act as a conductor. Individual cables are often placed in locations that feed to a multi-zone control system, enabling users to identify the area an alert originates from. Some systems allow distance reading, which lets businesses run a single long cable across zones and receive a distance measurement within a few feet of the leak when it occurs. Often, this information is supplemented by a cable route map in the control system.

With the variety of leak detection options available, it is important to evaluate the types of monitoring required and the suitable implementations. Some factors to consider include: the area/s being monitored, adjustable sensitivity of the sensor, reset time if triggered, costs and simplicity of installation, scalability, and ease of integration. Network Technologies Inc (NTI) offers a wide range of leak detection sensors compatible with its ENVIROMUX